Project Results

Publications and Conference Presentations

I. M. Łakomski, G. Tosik, P. Niedzielski: Optical Fiber Sensor for PVC Sheet Piles Monitoring. Electronics 10 (2021), 1604-1613. DOI:10.3390/electronics10131604

II. Mateusz Łakomski, Grzegorz Tosik, Brillouin backscattering analysis in recent generation of telecom optical fibers. Optica Applicata 52 (2022), 405-416. DOI: 10.37190/oa220307

III. R. Anyszka, D. M. Bieliński, M. Siciński, T. Gozdek, M. Okraska, J. Chudzik, M. Imiela, J. Wręczycki, D. Pietrzak, J. Gralewski, M. Maciejewska:Improving adhesion between acrylonitrile-butadiene rubber and glass fiber cord by covalent bonding and secondary polar interactions. Polymer Bulletin, 80 (2023), 3197-3226. DOI: 10.1007/s00289-022-04198-y

IV. D. M. Bieliński: Functional hybrid composites with designed properties - presentation in the "Scientists of the future - prelude to innovation, Tech science" section during the Intelligent Development Forum, Toruń, September 26-29, 2021.

V. J. Gralewski, M. Siciński: Fibrous structures for reinforcing composites - presentation during the Meeting of Partners, Members and Friends of the Polish Cluster of Composite Technologies (PKTK), which took place on March 2, 2022 in a virtual format.

Patents and Know-How

I. Application marked with number P.440 470: Compatibilizer improving the adhesion of profiles from chemically or thermoplastically cured resins, possibly reinforced with mineral fibers added in an amount not exceeding 20-80% by volume of the profile, reinforcing a polymer matrix from polyvinyl chloride to this matrix, and the method of applying this compatibilizer to the surface of a thermoplastic resin (25.02.2022).

Patent claims:

1. A compatibilizer improving the adhesion of profiles from chemically or thermally cured resins, optionally reinforced with mineral fibers added in an amount not exceeding 65-75% by weight of the profile, reinforcing a polymer matrix from polyvinyl chloride to this matrix, characterized in that the profile heated to a temperature higher by 10-30 °C than the melting temperature of the resin or resin mixture whose layer is to be coated, is moved in a chamber containing a fluidized bed of powdered resin from polyester, vinyl ester, epoxy, or a mixture of these resins having the composition defined above, with a grain size of 45-63 µm, at a speed and temperature chosen so that on the profile section staying in the chamber, the temperature on its surface remains at least 10 °C above the melting temperature of the powdered resin or resin mixture, allowing the resin layer provided in powdered form to settle on the surface of the compatibilizer in a molten state subject to a pre-crosslinking process, and after cooling the profile, the thickness of the powdered resin layer applied to the profile is not greater than 200 µm, preferably 50-100 µm.

2. A method of applying a compatibilizer improving the adhesion of profiles from chemically or thermoplastically cured resins, optionally reinforced with mineral fibers added in an amount not exceeding 20-80% by volume of the profile, reinforcing a polymer matrix from polyvinyl chloride to this matrix, characterized in that the profile heated to a temperature higher by 10-30 °C than the melting temperature of the resin or resin mixture whose layer is to be coated, is moved in a chamber containing a fluidized bed of powdered resin from polyester, vinyl ester, epoxy, or a mixture of these resins having the composition defined above, with a grain size of 45-63 µm, at a speed and temperature chosen so that on the profile section staying in the chamber, the temperature on its surface remains at least 10 °C above the melting temperature of the powdered resin or resin mixture, allowing the resin layer provided in powdered form to settle on the surface of the compatibilizer in a molten state subject to a pre-crosslinking process, and after cooling the profile, the thickness of the powdered resin layer applied to the profile is not greater than 200 µm, preferably 50-100 µm.

II. Application marked with number P.440 471: Fibrous structure from basalt fibers for reinforcing composite based on polyvinyl chloride (25.02.2022).

Patent claims:

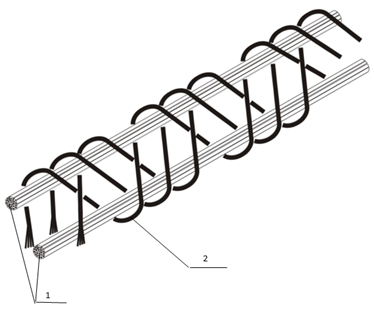

1. Fibrous structure from basalt fibers for reinforcing composite based on polyvinyl chloride, with the addition of poly(ethylene terephthalate) fibers - Fig. 6, modified pro-adhesively with resin, characterized in that it consists of a tape composed of braids connected by stitching or thermally, each braid consisting of two cores (1) of continuous basalt fibers with linear mass of 136 - 4800 tex, braided with one layer of yarn (2) of monofilament from poly(ethylene terephthalate) with a diameter of 0.09 mm, with the content of basalt fibers and poly(ethylene terephthalate) monofilament in the tape being preferably 4:1 by volume, poly(ethylene terephthalate) monofilament 27.2% by volume, and the tape is impregnated with epoxy or polyester resin with a viscosity of 500 - 3000 mPas at a temperature of 40-60°C, containing preferably up to 5% by weight of a pro-adhesive agent in the form of functional silane, with the volumetric content of resin in the tape being 60 ±5%.

2. Fibrous structure according to claim 1, characterized in that the tape consists of three braids connected by a flat seam or thermally by heating at a temperature of 255±5°C.

3. Fibrous structure according to claim 1, characterized in that the braids contain basalt rovings from basalt fibers preferably with a linear mass of 2000 tex.

4. Fibrous structure according to claim 3, characterized in that as a functional silane, the resin contains N-(2-aminoethyl)-(3-aminopropyl)trimethoxysilane.

Fig. 6 Fibrous structure from basalt fibers for reinforcing composite based on polyvinyl chloride, with the addition of poly(ethylene terephthalate) fibers.

III. Know-How: Optoelectronic system technology for monitoring the condition of vinyl sheet piling made of PVC (2023).

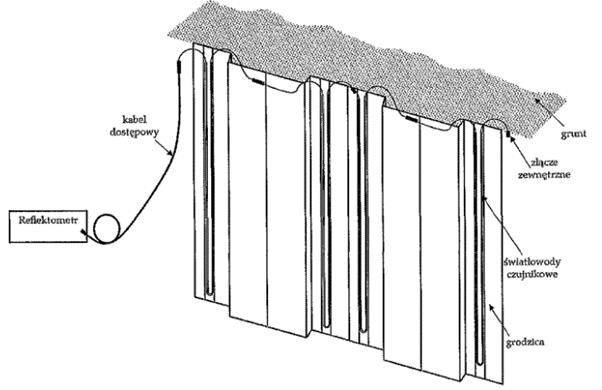

The know-how concerns the developed optical fiber sensor for measuring deformations, intended for structural monitoring, among others, of vinyl sheet piles made of polyvinyl chloride. Figure 7 presents the concept of a measurement system utilizing integrated optical fiber sensors with sheet piles. For the observation of stress changes on the optical fiber, a Brillouin backscattering reflectometer is used. Due to the low attenuation of optical fibers, the distance of the access cable can range from a few meters to several kilometers. Integrated optical fiber sensors for stress measurement, unlike electrical counterparts, enable distributed readings of strain values (over the entire length of the sensing optical fiber). Due to the integration method allowing U-shaped bending of the optical fiber in the lower part of the sheet pile, it is possible to serially connect subsequent sensor structures. The method of making connections can be realized by using optical fiber connectors or splices.

Fig. 7 Concept of structural monitoring system for PVC sheet piles.

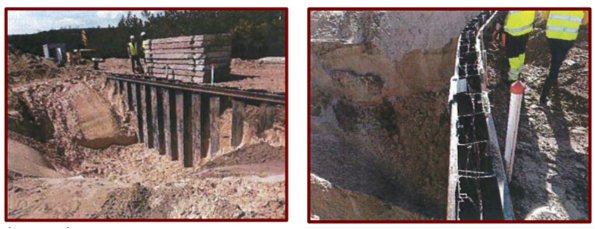

Fig. 8 Photos from field tests.