Project summary

The aim of the project was to develop a reinforcement material and technology as well as an electronic system for monitoring the degree of deflection of elements of a vinyl (PVC) sheet pile assembly used in the construction of bulkheads and retaining walls applied for construction and civil engineering purposes.

The project involved the development of a range of fabrics of different weaves (patent application P.440 471) and a surface modification technology for pultruded fibre-reinforced plastic flats (patent application P.440 470) to improve the mechanical strength of the cofferdams without an excessive increase in their stiffness, as is the case with the use of glass fibre-filled PVC. An additional element of the project was the selection of fibre optics, the development of a method for their installation on the sheet piles and the design of a sheet pile metering system to monitor the internal stress state and/or the degree of deflection of the sheet piles during use.

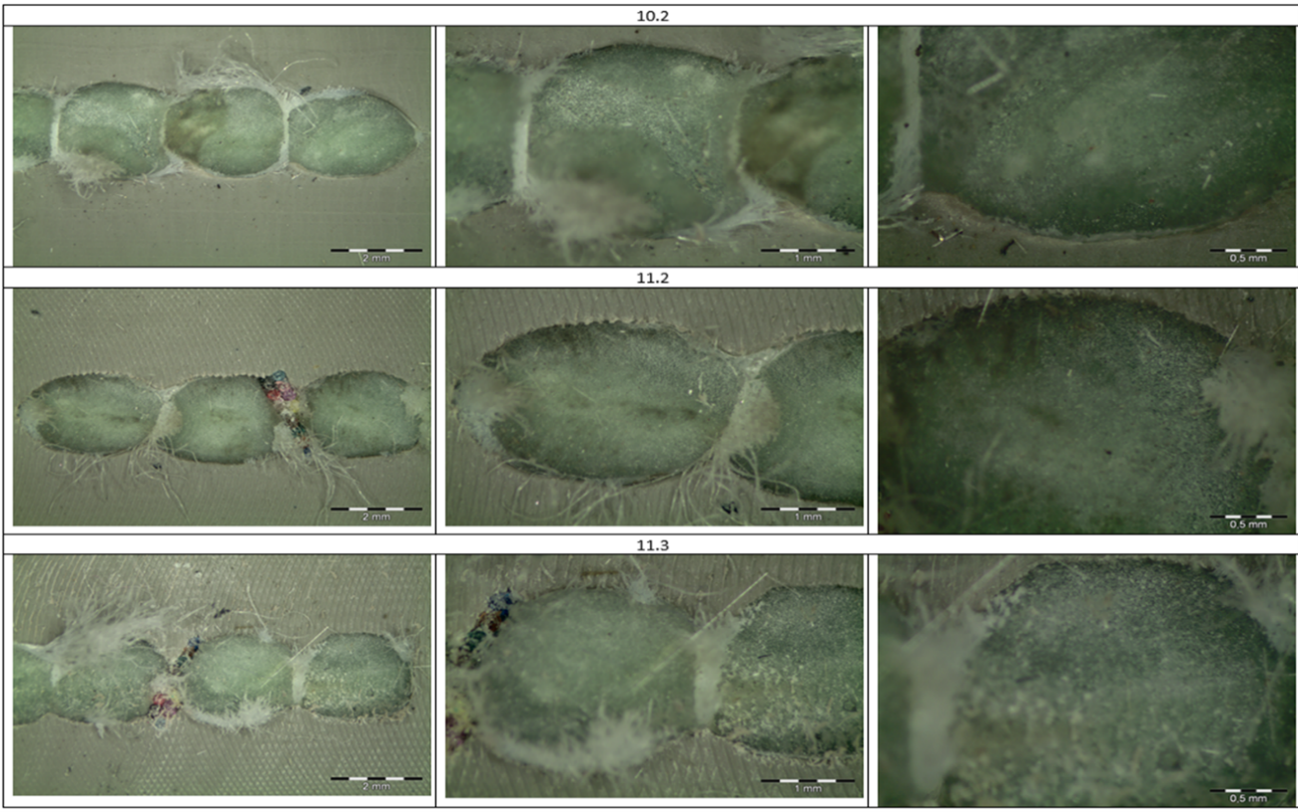

Fig. 1 Cross-sections of the composite with the snowman structure used, developed in the project: 10.2 - 2x snowman, 11.2 and 11.3 - 2x snowman with fibre optics.

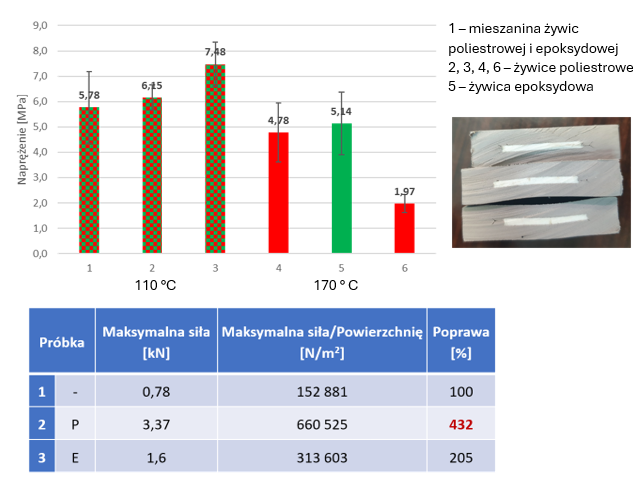

Figure 2 Strength effects of pultruded flat bar surface modification applied to reinforce PVC composites.

Idea of monitoring the deflection/stress generated in the bulkhead material.

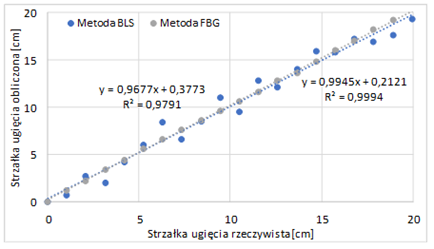

Fig. 3 Comparison of the actual deflection value of the PVC profile with the value calculated from the experiment.

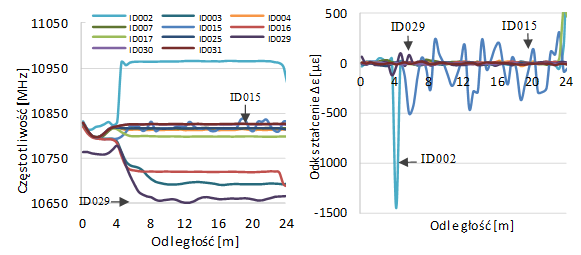

Fig. 4 Influence of the type of optical fibre on the accuracy of strain measurement by the BLS method.

Fig. 5 Laboratory workstation.